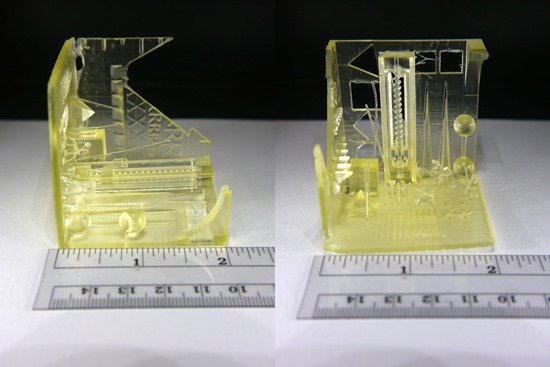

My first print ever... and it failed!

Truth be told, I expected it to fail in several areas, so it was also a success in that it taught me a great many things about printing on the Form 1 3D printer. This mangled mess is a print of a model built specifically for stress-testing various properties of the Form 1 and Formlabs’ clear resin. I’ll explain each of the different parts of the print and model below, and if they were successful or failures (and if I know why).

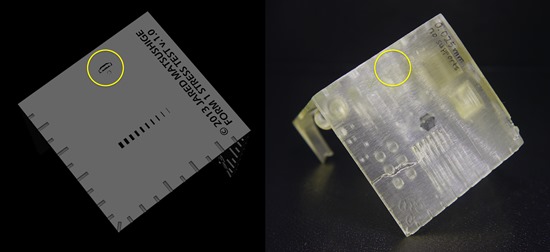

The Form 1 Stress Test v.1.0

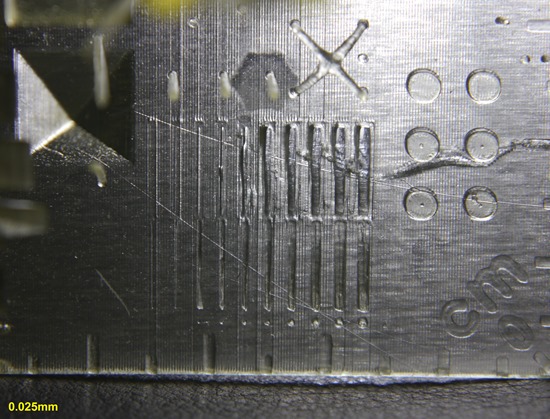

The part was printed using the 0.025mm setting for clear resin, and took about 9 hours to print. The dimensions are 2x2x2 in. No supports were generated for this print, so the part was printed completely flat to the build platform. Because the part stuck so strongly to the base, I had to use a little brute force to chisel and pry it off the platform. This resulted in some warping on the base, and also a nasty gouge on the base’s flat surface.

The overall size is pretty spot-on; I was actually amazed at just how close it was to the dimensions I modeled!

Test Structures

Below is a summary of all the different test structures built into the model, labeled from A to Z. Each of the print’s test structures will be looked at in detail in the sections following.

A: Inches in 0.25in increments, raised lines on front, engraved on back

B: Centimeters in 0.5cm increments, raised lines on top, engraved on bottom

C: Engraved and raised lettering (Rs), depth sharpness (Xs)

D: Overhang angle tests

E: Negative shapes

F: Sharp edge test

G: Beveled hole

H: Fine mesh, diagonal

I: Fine mesh, horizontal, with circular “window”

J: Inverted pyramid test

K: Pyramid

L: Cube

M: Fine point tip test, flat wide

N: Fine point tip test, cone tip

O: Flagpole holder and hinge pin

P: Straight and curved cylinders bridge test

Q: Wall, gap, and cylinder thickness tests

R: Linear drive crank handle with rotating knob, assembled mechanical test

S: Linear drive assembly, assembled mechanical test

T: Hollow spheres with breakable inner beads and poking tool with holding pin

U: Flagpole with flag

V: Beveled cube

W: Linear drive gear drive pin

X: Flexibility test strips

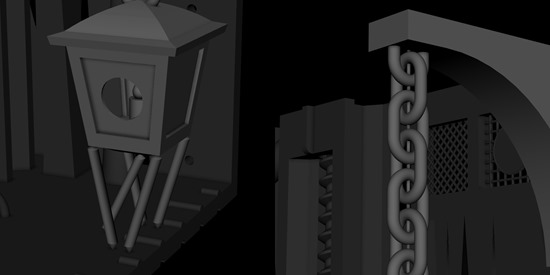

Y: Lantern with arm and chain, assembled chain test

Z: Interlocking block with pegs

Test A

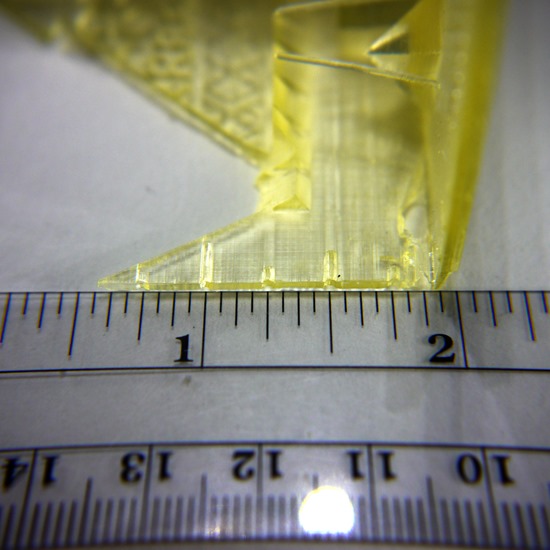

Test A is meant to test inch accuracy, and to see how well it handles printing flat, vertical surfaces.

Despite the wall for the inches not printing completely due to the “snowball effect” failure by Test J, the raised increment lines show that the vertical printing was actually printing quite accurately. You can see in this photo that the lines are lining up very well with the increments on the ruler.

There is a lot of horizontal streaking in the print. Other Form 1 users have noted that they’ve seen streaks in their prints as well, but they could not feel them. The streaks in this print can definitely be felt, and they are quite extreme. I’m not sure of the cause, but I have seen suggestions that angling flat surfaces in PreForm can help avoid this problem.

The backside of the inch wall has engraved lines instead of raised lines to help keep it flat when set on a flat surface. It was rather difficult to photograph these, so hopefully you can see them well enough in this photo. They printed fairly well, though the print quality on the backside came out very uneven.

At the base of the wall, where the vertical face meets the horizontal base, a number of gaping holes formed for reasons unknown.

Test A findings: Vertical accuracy is excellent, but the printer appears to have difficulty printing completely flat vertical surfaces. This may be a product of the cured resin being too soft and shifting the part around during the peel process, but this is just a theory. It could also be due to the build platform shifting around or the laser not tracing as precisely as it should. I’m not certain why the holes formed near the bottom of the part, so I’ll have to keep a lookout for these kinds of errors later.

Test B

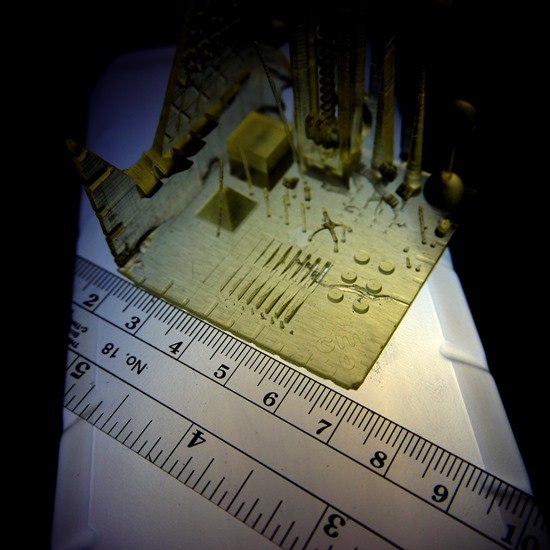

This test is meant to test accuracy, much like Test A, although with centimeters instead of inches, as well as how well the printer handles a large, flat surface printed directly on the build platform.

I had a very difficult time taking photos of this particular test since the base is warped, and the raised lines oddly did not print as high as they should have. The photo above is contrast-adjusted so you can see the lines better. Since the photo was taken at an angle, you’ll have to take my word that all the increment lines line up with the ruler just about perfect.

Engraved lines were also designed into the bottom, opposite the raised lines, but they did not print well at all. The grooves you see along the bottom edge in the photo is pretty much all that’s there. The rest of the bottom printed completely flat, save for a few of the holes from Test Q.

You can see in this photo that there’s actually supposed to be some engraved lettering on the bottom of the print (copyright and version information), along with some engraved lines for the centimeter increments, and holes for other test parts. None of the text or engraved lines printed properly.

For the first layer of any print, the printer appears to “over-cure” the resin to the build platform by tracing over the first layer six times. This makes the first layer of resin a lot harder than subsequent layers to keep it adhered to the build platform. For about 2mm afterward, the laser traces twice, then traces just once per layer after that.

The light of the laser bleeds a little as it traces over the resin. My theory is that when the laser passes over the resin once, the bleed does not affect the surrounding resin very much. Thus, on layers where the laser only passes once, the detail can be very fine. On the layers where the laser passes more than once, the surrounding resin is exposed to the laser bleed more often, which causes a larger area to harden. Any details built into these multi-pass layers will likely be distorted or lost.

A finding that supports this theory is that the base of nearly every object I’ve printed so far exhibits a very slight beveled edge, with the part closest to the build platform being wider than layers following it.

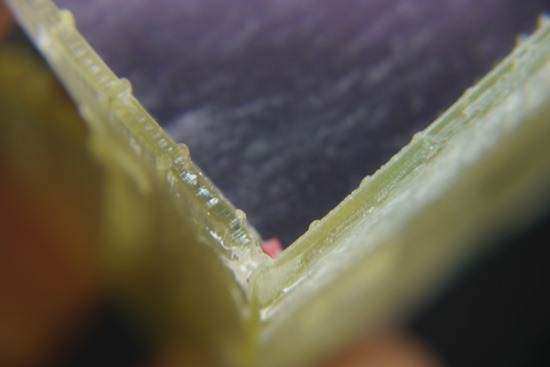

An interesting effect (or side effect) of the multiple laser trace layers is that the laser paths show up much more clearly on flat surfaces. In the photo below, the left shows the result of two laser passes on a flat surface, while the right shows a single laser pass at the top of the completed print.

I’ve found that the centimeter increment lines did not print as tall as they did on the inch wall in Test A. The lines themselves are supposed to be 0.5mm tall, and the inch lines printed at that correct height. The centimeter lines printed at only around 0.25mm tall. I’m not sure why this occurred, but I’ll definitely have to keep this in mind for future prints.

Test B findings: Horizontal accuracy seems to be just as good as the vertical accuracy. Anything printed with the part flat to the bottom doesn’t seem to hold detail properly, so either the part needs to be designed with this in mind, or supports are necessary. Building an object flat to the base can also make it difficult to remove the part without damaging or warping it. For anything that needs to be printed with a flat surface, raising the flat surface higher than 2mm can help create a smoother surface. Small details may not print as tall as they should.

Test C

Test C is to test how well it can handle text; R and X were chosen for visibility, straight and angled sides, and curves.

Unfortunately, since a large portion of the wall failed because of the Test J snowball, I’m not able to see how well very small engraved letters and very large raised letters would do. On the other hand, very large engraved letters and very small raised letters appear to print very nice and crisp. There are some distortions on some of the smaller lettering, but considering the smallest letter is less than 1.8 mm tall, I find that they printed out this well to be quite a feat. The engraved depth test of the letter X ended up having very smooth corners on the shallowest depth (0.1 mm), and is barely visible. A depth of 0.2 mm or more seems to work better if the lettering needs to be clearly visible.

Test C findings: Because a large portion of the test failed to print, I can only say that very small raised lettering and very large engraved lettering print very well. Engraved lettering should be at least 0.2mm deep to be more clearly visible, as the edges do not seem to hold very sharp angles when the surrounding area is too shallow.

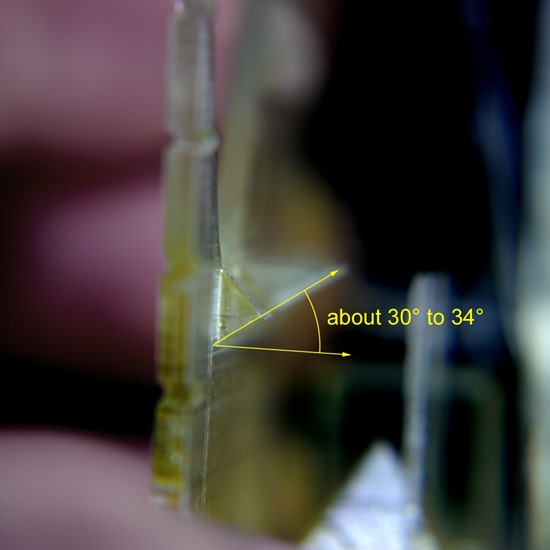

Test D

Test D is meant to at what length and angle of one-sided overhangs a print would fail at before support structures would be required.

The test was a success in that most of the overhangs printed, but the two with the most extreme angles failed because the inverted pyramid from Test J failed and snowballed. I’ll have to redesign this section so that if Test J fails again, it won’t affect prints further up the print.

The overhangs that unfortunately failed hand angles roughly 30-34° from horizontal. Considering how some of the completely horizontal structures from other tests managed to print (Test P, for example), the failed overhangs probably would have printed just fine. One of the failed overhangs actually partially printed to its correct length of about 6mm.

I would like to try more extreme angles in another revision.

Test D findings: Inconclusive, but most overhangs seemed to print very well. Angles greater than 34° from horizontal printed just fine. It appears that even at 34°, overhangs can print decently to at least 6mm from the supporting wall, and likely even further.

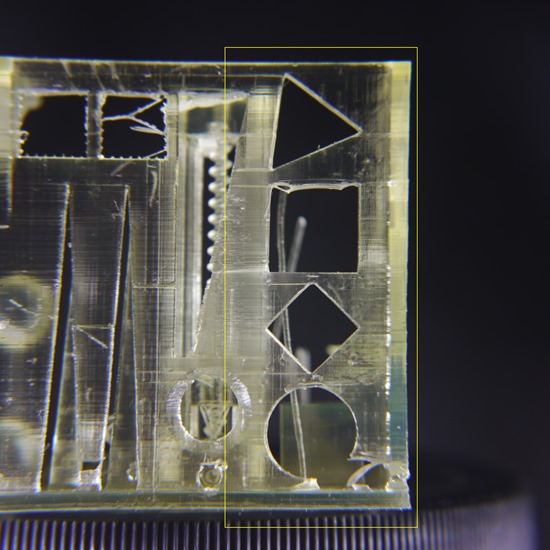

Test E

Test E is meant to see how well the printer handles certain basic negative shapes.

The most difficult shape for the printer would have been the square situated with a completely horizontal ceiling. Predictably, the square came out the least perfect, but I was actually very surprised that the shape managed to print at all at the top. You can see that there is some odd bending on the upper edge of the shape; this is where the resin wasn’t able to stay completely rigid and horizontal during the peel process. The subsequent layers hardened the loose resin and was able to form a stronger structure for the rest of the layers to adhere to.

The circle at the bottom was a success, but the hole at the bottom right is some sort of print error I need to study more. It’s similar and connected to the print errors along the bottom of Test A’s wall.

Test E findings: Most shapes will likely print very well, though straight overhangs should be used very sparingly and carefully. A bigger overhang may have caused layers above it to fail, snowballing like the error seen on the Test A wall.

Test F

Test F tests how well the printer and resin can handle a sharp, knife-like edge. This is meant to test both sharpness and strength.

For the most part, the printer and resin handled the sharpness test very nicely. The imperfection you see in the photo along the edge is from me running my finger over it. The edge is not sharp at all, and is actually quite brittle. Any details printed with such fine features should be handled very delicately. If you decide to make any cutting tools with this resin, it would probably be best to keep the sharpened edge of the blade short and thick so it’s not as prone to breakage. A wide, thin blade edge will likely end up looking like it’s seen many battles in no time.

Test F findings: Fine edges can be printed without problem, at least along the vertical (Z) axis. Such edges can be very fragile, so handle them with care. Edges that need to be kept sharp for utility should keep the sharpened edge short and thick.

Test G

Test G looks at how well a circular hole with a bevel prints.

The streakiness of the print mars an otherwise beautiful structure. Printing this horizontally would likely look a lot better. Other than that, it printed just fine.

Test G findings: Horizontal streaking caused the structure to not appear as nice as it actually is. Printing it horizontally may result in a better appearance.

Tests H and I

Test H is meant to see how well a fine mesh would print at the Form 1’s advertised minimum detail size (300 microns, or 0.3mm). Test I is meant to test a similarly-detailed mesh (also at the minimum detail size of 0.3mm), but with a “window” built into the mesh, like something you’d expect to see in an Asian-inspired architectural building, perhaps.

As you can see, both tests failed miserably. I had hoped that, despite being very finely-detailed structures likely prone to failure, the close spacing of the spaces between the meshes would keep them strong enough to print.

Test H apparently failed as the delicate structures sheared off at the first A-shaped point. Further parts of the mesh likely began to clump and become stuck to the resin tank, eventually pulled off by some of the other layers.

Test I failed at the first horizontal strip, and subsequent layers of the mesh and window also failed because of it. You can see where the first horizontal layer pulled away from the first vertical parts of the mesh.

Tests H and I findings: Despite being rather densely-packed, very small, detailed structures don’t hold up well. They may need some kind of supporting structure to build them, but they’d need to be something the PreForm software is not yet capable of producing at this moment in time. Details should be built at least some amount wider in diameter than 0.3mm if they need to be fine structures such as those modeled in here.

Test J

Test J is meant to test how well the Form 1 and resin can print a large inverted structure from a very small support.

FAIL! This was pretty much expected, however.

A small square of cured resin was found stuck to the bottom of the resin tank where the inverted pyramid should have printed. The single, tiny support at the base of the inverted pyramid was simply not strong enough to cope with the force of the suction that the bottom of the resin tank pulls with.

Unfortunately, the failed pyramid was also the cause of the huge V-shaped error on the vertical wall next to it. The little square of cured resin stuck to the bottom of the resin tank happened to vertically overlap the two overhangs above it, so when the print progressed to those overhangs, the cured resin blocked the laser spot from forming them properly. The square “snowballed” as it pulled small amounts of cured resin from each layer printed afterward, growing larger and larger as the print progressed.

Test J findings: The strength of support structures must provide greater holding power than that of the suction strength of the resin tank peel process. There’s probably some mathematical equation for this, but as an artist it wouldn’t do me any good (I wouldn’t even be able to explain it to you, probably). Parts that are meant to fail, or are expected to have a possibly high risk of failing, should be designed with a clear vertical print path.

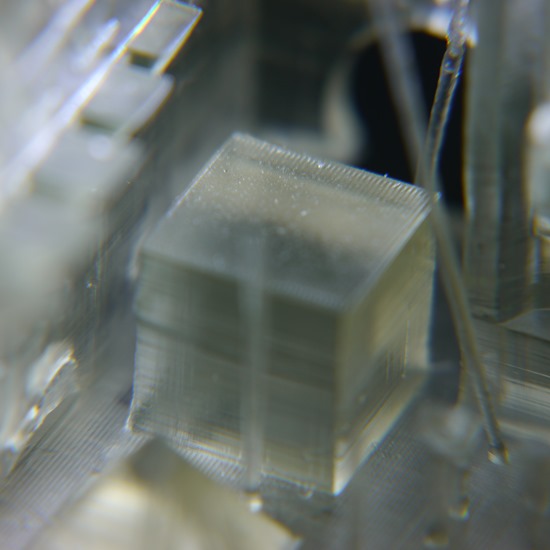

Tests K and L

Tests K and L were just beauty tests, to see how well the printer could print out solid faceted shapes.

These two came out quite beautiful, despite the facets not being quite as flat as I had hoped. Angling either of these pieces would likely not improve the streaky quality of the flat surfaces, as demonstrated by the angled sides of the pyramid.

Even on the flattest surface, the top of the cube, there was some streakiness. Still, the cube is just 1cm³, so the small striations could probably not be felt very easily. For perfect surfaces, some kind of post processing would definitely be necessary.

Tests K and L findings: Solid, faceted shapes print very nicely, though streaking is visible on the faceted surfaces. Perfectly flat faces are likely not possible on this printer, though it does come very close. For crystal-clear, polished-like surfaces, some kind of post processing is necessary, whether it be via an acrylic sealer, or some other method.

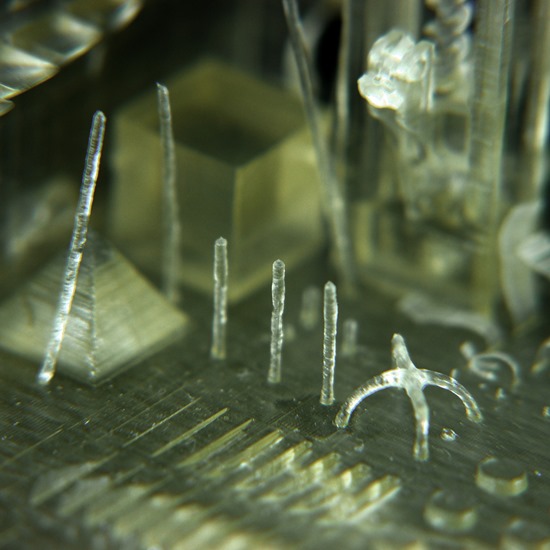

Tests M and N

Tests M and N test how well the Form 1 can print very tiny points. M is a wedge shape, flat on both sides with a tapered point, and N is a cone. On the wall behind it, cutouts represent about how high the point should be if it were able to print that far.

As you can see in the above photo, the wedge (M) managed to get about 2mm from the expected tip length, and the cone (N) got about 4mm before the printer could not print any smaller. Given that the PreForm software indicates that the laser should have hit that high, it’s likely the tips got too delicate to stay stuck to the part and got stuck to the bottom of the resin tank instead.

Measuring things out, the wedge failed at around 0.23mm of the point’s width, while the cone failed when the diameter was about 0.47mm.

Tests M and N findings: The Form 1 and clear resin is capable of creating some very fine points, within reason. More testing would be required to get a better idea for what widths and diameters are best for certain structures to print.

Test O

Test O is a flagpole holder for the flagpole in Test U and a pin to lock the holder into a hinge assembly on Test S.

Unfortunately, Test U (the flagpole with flag) failed, so I wasn’t able to test fit the parts together. However, as you can see above, the holder itself looks pretty mangled. I doubt the part would have worked at all. The holder is less than 3mm along its longest dimension, so it was kind of a reach to expect this part to print properly to begin with. The pin is also very tiny, so no surprise that it didn’t print too cleanly, but it held rather well to the tiny support it was attached to.

After taking the photos of the attached part, I separated them from the supports to try and fit them to the mount on Test S.

These parts are tiny. I actually lost the pin while handling it and had to search the carpet for a while to find it (the part being clear didn’t help at all). I had to use tweezers to place them on the mount on the Test S structure.

The holes to hold the pin were printed a bit too large for some reason, both on the holder and on the mount, so the holder didn’t sit properly on the mount and the pin didn’t stay seated. The fit was very loose, and definitely did not move the way I expected it to.

Test O findings: Tiny parts, even at 0.025mm layer height, don’t seem to print too well, though it could be that the supports I built for the parts were too flimsy to support the part during the peel process. The holes may also need to be designed a little undersized to accommodate for the print offset, but more testing is required to know for sure.

Test P

Test P is designed to test small overhanging structures supported far off to the side.

This one actually surprised the hell out of me. I really did not think would do this well! If I were to guess why this particular structure survived, it’s because of its “X” shape, and the fact that one of the intersecting shapes is an arch. As the layers reached the straight horizontal bar connecting the straight vertical cylinders, they met the arch at the center, which supported it as the resin tank peeled away. It’s also surprisingly rigid, though this may be the result of curing in the sun.

Test P findings: Completely horizontal structures appear to form fine if supported. Arches also seem to work fine. It would be interesting to see how these intersecting structures would work if they were separate from each other.

Test Q

Test Q is meant to test the printable size and durability of wall, cylinder, and gap thicknesses ranging from 0.1mm to 1.0mm.

From what I learned about the Form 1 before it was released, the 0.3mm laser spot size meant that while walls would likely be limited to printing 0.3mm or larger, but gaps could be printed smaller.

Unfortunately, because the first several layers were over-cured by several laser passes, the gaps along the first 18 layers or so closed up on the smaller gaps and distorted the larger ones. The rest of the test printed decently.

0.3mm seems to be the baseline for prints here. Anything smaller doesn’t appear to print, whether it’s a gap, wall, or cylinder. 0.2mm and 0.1mm walls didn’t appear to print past the first layer above the floor, and the walls of gaps at this size appear to have fused together. Cylinders didn’t even print at all.

At 0.3mm, the wall printed to the correct height and shape, but because it was so flimsy, it cured skewed. Similarly, the cylinder printed at 0.3mm appears to have pulled away from the print, being too weak to stay connected to the floor. The 0.3mm gap created a very, very fine, but shallow channel.

Past 0.3mm, walls became more rigid and straight, and cylinders stayed connected to the base. If the base layers were not over-cured, the gaps may have printed a lot cleaner. Neither the walls nor the gaps appeared to have printed at the correct size, with the 1.0mm sizes printing around 0.8mm instead.

The flagpole supports were supposed to be connected to some of the larger cylinders, but this might have been a bad idea considering how small and delicate the cylinders are. This may also have been a contributing factor to the flagpole failing to print.

Test Q findings: 0.3mm is the smallest width and diameter that appears to print correctly. Cylinders at this size may not have enough strength to withstand the turbulence caused by the peel process and could break away from the base. 0.4mm appears to be a good size for walls to print rigidly, though this would likely change depending on the distance of the wall from its base. Cylinders at these sizes do not appear to hold the correct diameter, so they should not be expected to be printed for any kind of precisely-sized parts.

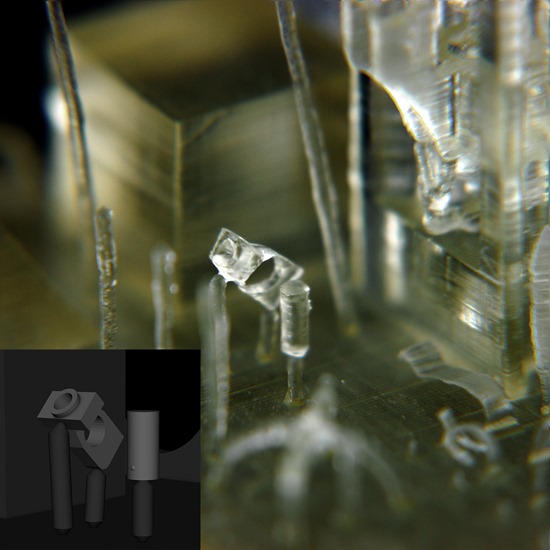

Test R

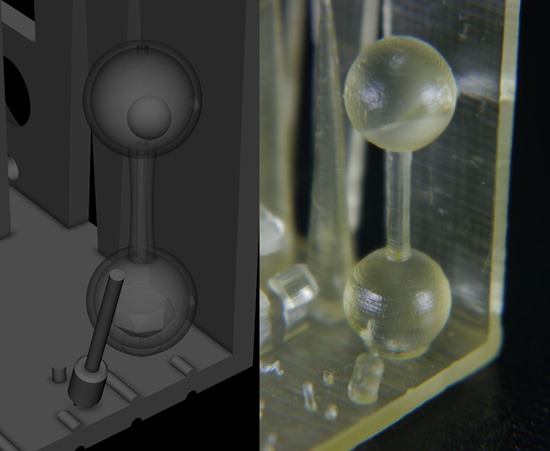

Test R is meant to test how well a two-piece handle and rotating knob can be printed fully-assembled.

It’s a little difficult to tell from the above photo, but that blob of cured resin is actually the very same part shown in the inset render (it failed, of course). I believe the failure was caused by supports that were too weak and too far apart, causing the part to pull away from them as the part got wider.

I thought it was really interesting how well the supports themselves printed, despite being failures. Look at that tall support! I measured it at 33.7mm long, with an average diameter of about 0.65mm. There’s an even taller support obscured from view by Test S (you can see the top of it in the first photo for Test S).

The gap between the rotating knob and the axle it rotated around was also probably far too small, as it appears the knob actually fused to the axle. I measured it to be about 0.31mm, so it may need to be wider. More likely, the knob and axle may just need to be more positively separated, either with stronger supports or perhaps some supports built between the two parts that can be broken off after printing.

Test R findings: Much stronger supports are necessary for objects that will have a lot of area of contact with the resin tank’s silicone layer to counter suction forces. Moving parts printed as one piece may also require one or more of the following to print successfully: a wider gap between the parts, stronger supports, breakaway supports between the moving parts. It may also depend on the orientation, size, and complexity of the part.

Test S

Test S is meant to test intricate mechanical parts printed as one piece, and consists of a screw driven by a gear that would be turned by hand via breakaway parts from tests R and W, a nut that travels up and down the screw, support beams that keep the nut from twisting as it travels up and down, and a flag that raises when it reaches the top (parts from Tests O and U).

I was disappointed that this test failed, but expected that it would. The screw itself printed beautifully, as did the nut and support beams. What didn’t print were the gears that were meant to drive the screw. All the parts were fused together at the base, so even if the gears did print, the whole assembly wouldn’t be able to move.

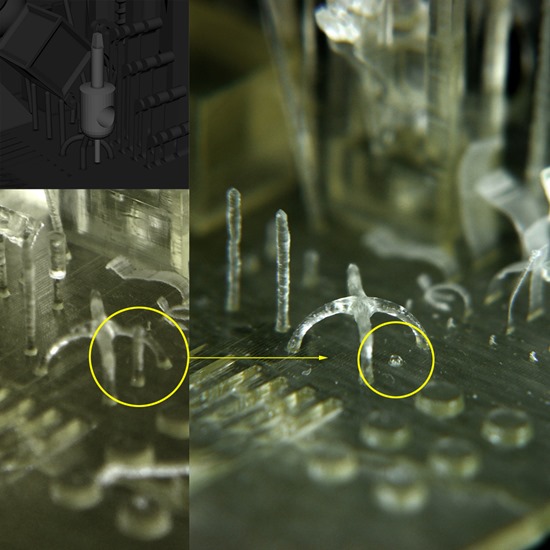

You can see the gears in the image above. I think I got a little too ambitious with this design, and probably should have waited to try this out after the rest of the tests were printed and studied. A large part of the problem was that the screw and gear were designed to be printed flat to the build platform, but because the first several layers were over-cured, all the little gaps I designed into that area fused together, guaranteeing the test’s failure. Below shows how the bottom should have looked, versus how it actually printed.

Test S findings: Mechanical parts printed as one piece need to be very thoughtfully-designed with knowledge of the printer and resin’s quirks and methods in mind. Larger gaps should be built between moving parts, and if parts will be built flat to the build platform, wider gaps need to be designed to compensate for the laser over-curing the resin.

Test T

Test T is designed to test resin evacuation holes and loose objects printed within hollow objects.

This print failed on a number of fronts. The two spheres were supposed to be completely hollow, but the evacuation hole at the top of the upper sphere was too small and was fused shut. The gemstone and sphere inside the two hollow spheres probably printed, but because the spheres were filled with resin and then left to cure in the sun, they’re now fused with the now-solid spheres. The cylinder connecting the two hollow spheres was built as a hollow tube so that the resin from the lower sphere could escape through the hole in the upper sphere, but the tube was too small and the resin too high viscosity, making it impossible for the resin to flow.

The evacuation hole at the top is 0.8mm in the model. The evacuation hole is meant to allow resin to flow out of a hollow structure. In this case, however, even if the hole did manage to print, the hole would be too small for even water to flow out of freely. The minimum hole size will need to be investigated further.

Some of the sun-solidified resin inside the hollow spheres appears to have cracked or split somehow. Since I didn’t see the splits occur when they happened, I’m not exactly sure when they actually formed, but I’m wondering if it may have had something to do with heat and/or the speed of the resin curing.

The object closer to the camera on the model is the poking device that would have been used to poke the objects in the hollow spheres free of their supports. The small peg to the left of the poker was supposed to be where the poker could be placed after use. The poker itself actually printed decently, as seen in this early photo shown below, taken before the part was left to cure in the sun. The poking part actually broke off as I handled the part over time, so it probably wouldn’t have been strong enough to poke objects free of their supports.

I apparently forgot to create the holes in the walls of the hollow spheres where the poker could poke the inner sphere and gemstone. If these holes had existed, the resin may have been able to escape the hollow cavities. (Update: It turns out I actually did create holes near the base of each object within the spheres, but I accidentally exported the model with a version that didn’t have the holes cut out yet. Oops...)

Test T findings: Evacuation holes need to be wider in diameter (0.8mm was too small, needs further testing). Hollow structures can create cavities filled with uncured liquid resin, creating a vacuum that can trap the resin inside without a means to escape. Holes to relieve this vacuum pressure should be made along the side of the structure that will be nearest to the build platform during printing. This allows air to be drawn into the cavity to relieve the vacuum pressure as the liquid resin is pulled out by the peel process. The diameter of the poking device should probably be wider to avoid being broken so easily. Uncured resin trapped within cavities may crack when exposed to heat and/or UV light.

Test U

Test U is meant to test thin cloth structures.

This part utterly failed to print properly. More than likely this was because the support structures were not built strong enough, and because they were built upon a very flimsy base to begin with (the top of the cylinders in Test Q).

The supports were positioned so that they wouldn’t deform the print too much. I had seen how PreForm’s built-in supports can leave unsightly bulges where the supports contact the part, so I wanted to keep the contact points of my supports small and minimal. Unfortunately, the low support count and weak contact points may have been this part’s undoing. Parts from other tests have also failed because of insufficient support strength (tests J, R, V, Y, and Z), so I’ll have to rethink them and re-support the parts for future prints of this part.

Test U findings: Failure likely caused by supports that are too weak. Uncertain if flag would have printed properly even with stronger supports. More testing required.

Test V

Test V is a diagonally-printed cube with inner beveled sides, meant to be removed from the print.

My intention was to have this cube be an impact test. The cube would be removed, then dropped and smashed with a hammer, but the three supports shown here were apparently not enough to support it during printing (lol).

Test V findings: More supports needed to print successfully.

Test W

Test W is a part designed to connect the rotating handle of Test R to the gear assembly of Test S, testing how separate parts can be interlocked together to create a working machine.

The part actually did print, though it didn’t finish successfully. The resulting piece was a mangled blob, much like Test R’s rotating handle. I thought I had the failed part lying around somewhere, but I may have lost it to the carpet. The circled structure on the left is actually the support structure that was meant to hold the part. The part itself failed to print properly, possibly having been pulled off by the peel process. I snapped the support off the base with tweezers to get better photos of Test P.

Test W findings: Insufficient supports for a successful print. I would need to increase the strength and/or amount of supports to properly print this part.

Test X

Test X is meant to test the flexibility of various heights of very thin strips of resin.

My little forest of piano hammers failed, sadly. There they were, standing so proud in the model file, then reduced to limply-hanging curls in the print. T_T)

Actually, most of the wider strips printed fairly decently. The thinner strips tore away from the print at their bases. The odd curling is partly due to the strips bunching up as they came out of the resin and cured in the sun curled, though the deformed “heads” were likely caused by the strips swaying in the turbulent resin pool after the peel process.

Since the strips didn’t cure straight up and down like I had hoped, this test is a partial failure. I was, however, able to see how well they flexed, despite not being straight. The strip teased (hehe) below is 3.0mm wide. All the strips were printed at a thickness of 0.3mm.

And video of it breaking:

As you can see, flexible parts may not last when printed with the clear resin. They may last longer if the part isn’t left to cure in the sun (the sun made the part especially rigid), but that’s for another test in another post.

Test X findings: Flexible parts won’t last long after curing out in the sun. Parts may be more flexible and may flex more before breaking if not left to cure in the sun or by other means. Thin parts that are also short in width may not withstand the printing process.

Test Y

Test Y is meant to test printing interlocking chains connected to an overhang.

Like a lot of the other tests, I didn’t build quite enough supports, or supports that were strong enough, for a successful print. I used five supports for the base of the lantern; next time I’ll use a lot more. I believe the print may have reached the top of the supports and may have even printed some of the lantern before the pull of the peel process tore it off the supports.

There may also not be enough support along the overhangs of the lantern. The arm holding the chain may have printed if the lantern and chain printed properly.

I’d really love to see this particular test print successfully, as it would be delightful to see the lantern dangling from the chain on the part. ^_^)

Test Y findings: Supports not strong enough to support printing the lantern and chain. The arm may have been fine despite the length of the overhang if the chain printed.

Test Z

Test Z is meant to test test how well the cured resin copes with frictional forces from the interlocking process, and how well the pieces fit together.

The challenge of printing an interlocking block, as I’ve found over the course of this test, is that there are a lot of quirks that need to be understood of the printer and the resin before something like this can be successful. For example, the pegs on the base did not print completely vertical, possibly due to the over-cure layers. The pegs also did not print to the correct height, similar to how the increment lines in Test B didn’t print as tall as they should have. I also noticed that the pegs did not print completely round; rather, they’re more oval in shape.

Because the brick itself failed to print (supports too weak), I wasn’t able to test if the brick would have interlocked snugly with the pegs.

Test Z findings: Stronger supports necessary for printing the block. Pegs possibly printed too close to the build platform, creating a wider peg base than there should be due to the multiple laser passes on the first several layers.

Other Findings

You can see in all the photos that the part is actually quite yellow. While the yellow is a little enhanced in some photos due to me being lazy and not color correcting every photo posted here, the resin is actually very noticeably yellow in person.

In the photo above, I’ve placed a freshly-printed part next to the print tested in this post. The colors have been adjusted to appear as close to how I see them in person. The yellow exhibits a kind of slight greenish tint, and in the sunlight both clear and yellowed resins have a rather pretty faint purplish hue.

I haven’t left any parts out in the sun for more than a few hours, so I can’t comment on how yellow parts can get.

I’ve also noticed some very strange phenomena happening on my prints, and they are actually very consistent. For example, have a look at some of these comparison photos between the yellowed part (0.025mm) and the clear part (0.1mm):

Do you see it? Here’s a little animated GIF to illustrate it better if you don’t notice it in the above images:

If you still don’t see it, I’m talking about the odd diagonal scratches. Initially, I thought it may have been from handling the part with tweezers as it first came out of the vat, but closer inspection revealed otherwise. These were not caused by mishandling the parts, otherwise the scratches wouldn’t be so strangely consistent between the two parts. The lines travel all the way to the base of the interlocking brick pegs, inside and over the structures of the wall and gap thickness tests, and over the pyramid--something not possible to do by just dragging a sharp object over the surface. I’ve also seen these lines on some of my other prints, so my guess is that there’s a surface imperfection somewhere inside the printer that’s messing up the prints, possibly on one of the mirrors. I’ll clean the main mirror under the resin tank to see it helps any.

Conclusion

Looking at all the results from the tests above, I can clearly see that 3D printing is definitely not for the general public, even with a printer that’s meant to be very straightforward to use. There are a lot of little things to pay attention to that can affect the output quality of the print. Seemingly little oversights can lead to catastrophic failures, such as Test J’s failure snowballing into Test A’s wall, and a lot of things I thought would print ended up failing because of certain technical reasons, like the holes on the base of the print closing up due to the early layers’ multiple laser passes.

The PreForm software isn’t quite at version 1.0 yet, but so far I really like the direction it’s headed. It’s very easy to use, and the interface is very clean. However, it’s also very basic at the moment, as there’s no way to precisely place parts on the build platform, nor is there a way to add or remove individual support structures built by the software. However, in some videos it appears that adding or removing individual structures may be a feature we’ll see in a future update. I’d very much like to see more precise control over the layer slice slider. In fact, this may be the #1 item on my wishlist for the software, as I felt like the current slider may have been skipping over layers instead of showing me everything. Maxim Lobovsky of Formlabs has mentioned below in the comments that precise control over the slice slider is actually possible by using the Up and Down arrow keys (Page Up and Page Down also works, in steps of 10). I tried it, and it’s awesome! If the keys don’t work, try clicking the slice slider handle; sometimes the slider seems to lose the connection to the keys and simply needs to be clicked to make it work again. Thanks for the tip, Maxim!

So far, I’m very impressed with the printer, and very happy that I’m now able to create stereolithography prints on my own. It’s not the end-all, be-all solution some may have been hoping for, but it’s very close. Looking at the output quality of some competing printers, I’d say the future is more than just bright, it’s blindingly bright.

I actually completed this print early last week, but it took me a while to compile all the information and photos. Other tests and findings are coming as I can find the time to post them. Thanks for reading this incredibly long post, and I hope you learned some stuff along with me! ^-^)/

UPDATE (6/14/2013): A typo was found in the “Tests M and N” section, where the units read “cm” instead of “mm” in both the text and image, but has now been fixed. (Thanks, ReadyGo! ^_^)

UPDATE (6/15/2013): My #1 wishlist item for PreFom had apparently been granted before I even knew I wanted it. I’ve added this information to the post. A typo was found in the Test Structures section, regarding text reading “0.5mm increments.” It has been corrected to read “0.5cm increments.” Test T has been updated with additional information regarding vacuum pressure of hollow structures and how holes can help drain them. (Thanks, Maxim Lobovsky and Mark Loit! ^_^)

UPDATE (10/28/2013): Looks like I mixed up the details of Tests F and G. All fixed now. (Thanks, Richard ! ^_^)

It is a great review and very professional. Thanks

ReplyDeleteA very helpful review for those of us who considers buying a Form1.

ReplyDeleteThanks a lot!

Epic documentation!

ReplyDeleteI think you've got a bit of engineer in you. Nicely done.

ReplyDeletebrilliant and amazingly thorough testing. We need a lot more of this so thank you. I ordered my Form1 back in November and can't wait for it to arrive....

ReplyDeleteTJ, this is an amazingly detailed review. That's a tough test part you've put together :) As I think you've understood, many of the problems were due to insufficiently supported geometry. We are adding support for supportedness coloring for parts without supports that we generated, so that should give you better ability to understand how this part would work ahead of time. Also, I encourage you to try this part again with new versions of the software and new materials. Would you be able to send us the model?

ReplyDeleteAs for your number one software request for finer control of the slider, it's been there the whole time :) Just use the up and down arrows on your keyboard to move one slice at a time.

Those diagonal lines are most likely on the bottom or type side of the tank. It may be possible to clean it, if not, when you replace the tank, it should improve.

-Max

cofounder, Formlabs

Thank you TJ! That is a torture test from HELL! :). I am hopeful that as the software improves over time and more resin derivatives are released, A-Z will become better and better. Although as you and Max mentioned, some support structures would help as well, so the future is looking bright with the Form1. You are one of the first to receive this awesome printer and I thank you tons for taking the time and effort you did with this! Thank you m8!

ReplyDeletegreat post, thanks for making it!

ReplyDeleteOn the subject of type-o's

"B: Centimeters in 0.5mm increments, raised lines on top, engraved on bottom"

That should be 0.5cm or 5mm not 0.5mm, or is that just the American metric system :P

would you mind sharing that stl file so some of us could give it a shot on our printers? :)

ReplyDeleteCouple of more thoughts.

ReplyDeleteFor the draining, you need at least 2 holes in the object, or it won't drain. You need to let air in to displace the fluid, otherwise you have a vacuum that will continue to hold the resin inside.

I would try the mesh again [H & I], but oriented on the horizontal plane. having the entire mesh form at once may help it survive the peel.

For the thin feature tests, try at 0, 45, & 90 degrees relative to the peel direction.

For the tall thin features, I would try adding a perpendicular temporary support.

I'd test some of these theories myslf, but I'm still waiting for my printer :)

Like everyone else I'm thankful and impressed by your work!

ReplyDeleteOne thing which might be insightful is to print with grey resin and see how the resin properties and the interaction with the laser change, and how these changes affect the print.

Thanks again!

Nice model! I'd love to attempt this on a B9Creator.

ReplyDeleteThanks! I would love to see it printed on one, actually; I'm a big fan of the B9C. ^_^ I regularly check in on the forums to see cool prints users have done and am always impressed.

DeleteI'll be releasing the model file eventually, though I can't say for sure when (hopefully soon). It'll be sometime after I can get everything to print fully and all the mechanical stuff works. It would be really cool to see how it turns out on a B9C. :)

Thanks, everyone! I honestly didn't expect this much of a response. A few comments here and there, maybe, but not nearly this much! :D

ReplyDeleteAlan: I have at least a few more tests to document, and I plan on continuing to post about my findings, interesting prints (successful, failed, awesome, crap, etc.), and more as time goes by, so hopefully I can help contribute more to the community. :)

Maxim: The supportedness coloring sounds great! That will be an excellent addition to the software, especially since most of the self-made supports I added were based on guesswork. I definitely realized from this test that supports are paramount to a successful print. I've already applied some of the knowledge gained to version 1.1, which I'll be posting a photo of shortly. It didn't come out perfect, but it's much closer than version 1 was.

Regarding the lines, I went and checked the resin tank and, sure enough, there were some very fine, barely-visible lines that had the same shape as the lines on my prints. I'll post about this in the near future with some pics if I can photograph the scratches.

Also, AWESOME about the up/down arrow control of the slice slider! I also tried the page up and page down keys and found that those work, too. Very cool! I'll fix the post to reflect this new knowledge. I will definitely try to print this test with newer software versions and materials as well! :D

Mark: Thanks for spotting that typo, it's now fixed. :)

I was going to save the info regarding drainage holes for another post (it's about a hollow sphere that destroys itself because of the lack of a hole to allow air in), but it's probably better that the info is mentioned here as well, since it's regarding the same principle. (updated Test T's information to reflect this)

Good idea about printing the thin structures at other relative angles. In the case of the flexibility tests, they were actually printed perpendicular to the resin tank's hinge. Unfortunately, they were just too long and thin to support their own weight properly, and their lopsided design (hammer-like head) didn't help, either. :P I just had an idea on how I might be able to get those guys to print straight, actually! I'll try it out in a future version.

I think I'll try printing the meshes in Test H and I along the horizontal plane as you've suggested. I'll orient the print so the wall the meshes are on is flat against the build platform, then use some of PreForm's supports to lift it away from the multi-pass layers. I think the peel process's suction may still tear the mesh away layer by layer, though, but it's worth testing... for science!

Paranoid Ponderings: I plan on sharing the STL file with everyone soon, but I'd like to make sure it can be printed properly before I do. It would suck if everyone tried to print it and ended up wasting resin on a model that's known to fail. ;)

Thank you so much for this post! I am still waiting for my printer to ship, but now I feel more prepared to start experimenting with it.

ReplyDeleteI would prefer if you did split this up into several test objects.

ReplyDeleteMany of the vertical walls printed would probably work perfectly fine if they where laid down.

I don't know why you did include the parts that you did now would never work (like the chain or the upside down pyramid), these will just create problems and destroy other parts of the print.

It might be more of interest to see what sort of thing can print and at what quality, and some that test minimum details etc.

Maybe I'll just create these myself :)

Anyhow, I'm impressed at the amount of work you put down and shared with good pictures + 3D renderings explaining your thoughts. Great work!

Good discussion! :) I had been typing this response for quite some time, but kept getting pulled away for some reason or another. Sorry I wasn't able to get back to you sooner.

DeleteThe vertical walls would print flatter with less streaking if they were laid horizontally, since the bottom wall/floor printed very nice and flat, but a lot of details that benefit from being printed away from the build platform would be distorted or lost. This is because the over-cured layers add about a 0.45-0.5mm extra material to the outer edges of anything printed directly on the build platform. This could change in the future as Formlabs gets feedback from us over time (hopefully! :D), but for now it means that fine details can get lost to them, like the engraved lines and copyright text on the bottom of the test object.

I have some suspicions that the horizontal streaks are related to details built along the same layer. The horizontal streaks are still there in other prints I did of this piece, but what struck me as very interesting is that a lot of the vertical streaks are in the same spots, even between prints done at different layer heights. There don't seem to be errors in the slices in PreForm. It could be something to do with layers separating from each other during the peel process.

Regarding including the parts I did know wouldn't work: the tests were built around what I had seen and learned from Formlabs' info, early user experiences, and what I had learned about how 3D printers and the Form 1 printed. They were designed around what I knew could fail or succeed, depending on the circumstances (I probably should have written that into the write-up lol). I really wanted to see for myself where they'd fail for sure by pushing limits, and how I could fix the failures afterward. Things like the totally unexpected snowball failure on the pyramid provided me with a very valuable lesson for future prints: if it could fail, try not to have anything above that part of the model. ;) It was because of this knowledge that I moved the longer overhang angle tests in Test D to the back corner, and the shorter ones to the front, just in case the replacement for the inverted pyramid test failed. Otherwise, all the known-working tests are pretty much built below tests known for failure.

Most of the tests themselves are separate objects in Maya. I'll be testing out some of the more delicate tests individually before v.1.2 to save on resin, then they're going back on the main part. The main reason I didn't separate out the tests is aesthetic; I wanted something that not only served a purpose, but also looked cool and was fun to play with. It's not quite at that "fun to play with" level just yet (maybe by v.1.3), but till tonight I'd been resisting tearing apart the more successful v.1.1... and it was really fun to see tests O, Y, and Z working! I was actually so intrigued by the dangling lantern that I played with it for quite a long time, almost like a cat would with string or something, so I think the "fun" part is really very close. ^-^)

Thank you for such an in-depth review.

ReplyDeleteI missed out on the Kickstarter because I felt the printer's promises were somewhat dubious in what could possibly be delivered, and this post seemed to pretty much confirm my doubts. I was considering paying the current asking price because my current FFF printer just can't hit such tiny details, but it seems that tiny details that don't have the strength that injection molded plastic can aren't really worth it to me.

If the price was $1000 less and the resin half price, it might be worth it. For the current prices I would expect to hit those points, though.

Clap clap clap :D

ReplyDeleteAnd thank you very much for sharing all this hard work. You did a terrific job, going further in nearly every test than one could expect.

Coming from FDM like many other readers, I can't wait for my Form1 to be shipped. Meanwhile, I'll keep on reading your blog again and again !

Thank you TJ! As a design engineer waiting for a Form1 to arrive at work, your tests and analysis are invaluable. Keep up the great work.

ReplyDeleteWhat a phenomenally thorough post! As a Form 1 owner just getting started learning the nuances of my printer, this read was extremely useful.

ReplyDeleteLooking forward to more info on your more recent, more successful print.

One small thing, I think you mixed up the sections for "G" and "F" in the text above (as of Oct 1, 2013).

You're totally right, I did mix those up... doh! xD

DeleteThanks for catching that. I'll get that fixed shortly. :)

Excellent review! Love the work. Any idea when the STL file will become available? I don't even plan to use it on a Form 1, I think it would be very interesting to use the test model on some of the other printers and find out how it stacks up with a direct comparison!

ReplyDeleteThanks! :)

DeleteI had originally planned on getting the file out early this month, but as plans tend to do, it kinda got pushed back because of other commitments (mostly day job stuff). The write-up on the successful print is half done, which I hope to get up and out soon, and I've actually learned quite a lot more about how to make prints more successful, so I've got to design that into the "release candidate" of the part. Sorry for the wait (both for you and for everyone who's been patiently waiting for it ^^;)

Thank you I am glad about the encouragement! I love your site, you post outstanding.Learn more

ReplyDeleteExcellent review! Any idea when the STL file will become available? I´d like to test my machine!

ReplyDeleteLove to test that on our FL2. Tip it up on a corner, and I bet almost all of that would work, AND it would be a doddle to take off the platform. I NEVER build things flat, if I can possibly avoid it! Gret test though, very interesting results!

ReplyDelete